Kargo System

Dock-Door Automation: Faster Throughput, Leaner Teams

| Kargo | 4 min

Why Speed, Not Just Claims, Drives Adoption

Labor now absorbs 55–70 percent of a warehouse’s operating budget and costs roughly $3.6 million per 100 heads¹. Hiring is harder, turnover is brutal, and every open position slows the dock. Loading dock automation—whether vision towers, RFID portals, or hybrid systems—lets one operator oversee the pallet flow of many, shrinking headcount without forcing overtime or sacrificing accuracy. Cutting loading dwell time also frees doors for more trucks, directly lifting daily volume.

How Automation Compresses Cycle Time

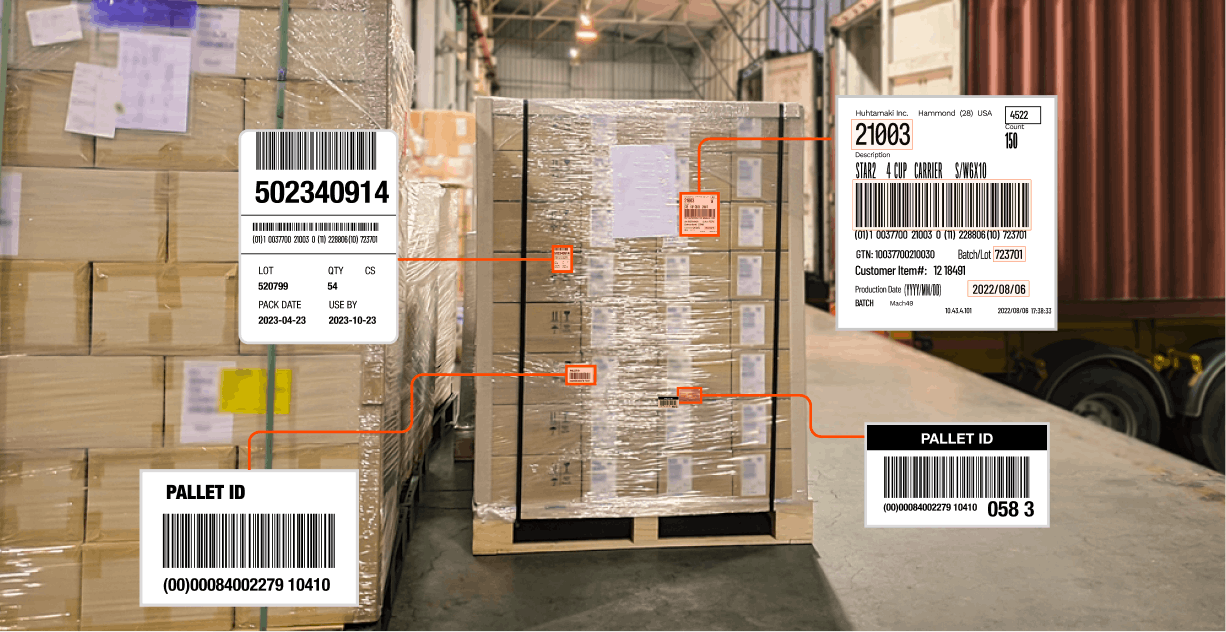

The best facilities move freight from trailer to rack in under four hours, yet others still burn up to forty-eight². The gap is rarely skill; it’s manual bottlenecks—forklifts queueing for scans, paperwork, and data entry. Vision towers snap a photo at full speed, extract bar-codes, dimensions, and even damage cues, then post to the WMS in seconds. RFID portals verify tagged loads, making label orientation irrelevant. Both eliminate the stop-and-scan pause that costs minutes per pallet—minutes that compound across shifts.

A good benchmark: 300 pallet scans per hour on a single automated lane⁴, far beyond what a handheld crew can sustain without fatigue. Case studies from automated “drive-by” loaders show even bigger leaps; one packaging plant chopped trailer unload time from an hour to just three minutes³.

Accuracy Still Matters—but as an Enabler, Not the Goal

High speeds are useless if data is wrong, which is why the leading vision provider, Kargo, touts a 99 percent-plus read rates⁵. That accuracy prevents the re-work loops that kill throughput later in the shift. Yes, better scans do reduce OS&D disputes—industry averages hover around two percent of unit loads⁶—but most buyers now see that as a side benefit of running a leaner dock, not the headline reason to implement loading dock automation.

Vendor

Best Fit

Watch Out

Cognex

Barcode-heavy ops that demand funnel-proof read rates

Extra lighting and IT integration add CapEx

Zebra

Sites already standardised on Zebra handhelds and RFID

Vision accuracy trails specialists at some angles

AbeTech

Tight footprints that need a quick, camera-first retrofit

Smaller customer base means fewer large-scale refs

RFID

Quick ROI and more ambiguous all-purpose warehouse environments

Cloud sync requires solid Wi-Fi or 5G on the dock

Building the Business Case Around Headcount and Dwell Time

- Map true dock labor cost. Include shift premiums and turnover training. Use the 55–70 percent rule¹ as a sanity check.

- Time your dock-to-stock cycle. If you beat the four-hour APQC target already, savings live in labor; if not, you gain both labor and velocity².

- Model door capacity. Every minute trimmed from unload frees dock doors for new loads—often worth another shift of output without new real estate.

- Project ROI conservatively. Independent studies peg payback at 18–24 months⁷; faster if you backfill fewer positions during peak or if you employ a subscription model like Kargo.

- Make sure it actually works. Many warehouse automation providers make grandioso claims about savings, however, when implemented they cause more headaches than solutions. If it is not accurate, it’s not speeding you up. Furthermore, push for a demo. At Kargo, we take the towers to you to ensure accuracy in your own warehouse environment.

Take-Home Message

Dock-door automation earns its keep by shrinking headcount and keeping freight moving, not merely by catching damage claims. Whether you lean toward Cognex precision, Zebra RFID synergy, Raptor’s small-footprint camera rig, or Kargo’s rapid-install vision towers, judge each system on how many minutes and bodies it saves per shift—and how quickly that translates into capacity you can sell.

Sources

- Meteor Space, “Learn About the Latest Warehouse Shortage Statistics,” Feb 27 2025 – labor share & $3.6 M cost. meteorspace.com

- Mecalux, “Dock to Stock: Efficiency Starts at the Loading Dock,” Mar 26 2021 – <4 hr vs 48 hr cycle times. mecalux.com

- Joloda Hydraroll Case Study, “Packaging Industry: Revolutionising Loading Processes,” line 7 – 60 → 3 min unload. joloda.com

- Gather AI, “Cold-Storage Drone Spec Sheet,” 2025 – 300 pallets/hour metric. gather.ai

- Cognex, “OCRMax: Offers 99% Accuracy,” Product page – read-rate reference. cognex.com

- Packaging Digest, “Mitigating Packaging Damage in the Supply Chain,” 2019 – average 2 % load damage. packagingdigest.com

- Addverb Blog, “How Robotics in Warehouse Maximizes ROI,” May 29 2025 – Deloitte 18–24 month ROI range.

Questions?

Connect With us

Ask us anything or drop your email to stay in touch