Kargo System

Dock Door Automation: How Smart Scanning Transforms the Modern Loading Dock

| Kargo | 5 min

Dock Door Automation: How Smart Scanning Transforms the Modern Loading Dock

If your loading dock feels like a daily fire drill, you’re not alone. The dock is where things go wrong first and get noticed last. It’s where pallets pile up, paperwork gets lost, and drivers wait longer than they should. But there’s a better way. Dock door automation and smart loading dock systems make the whole process smoother, faster, and way more accurate.

What Is Dock Door Automation and Why Is It Critical for Warehouse Efficiency?

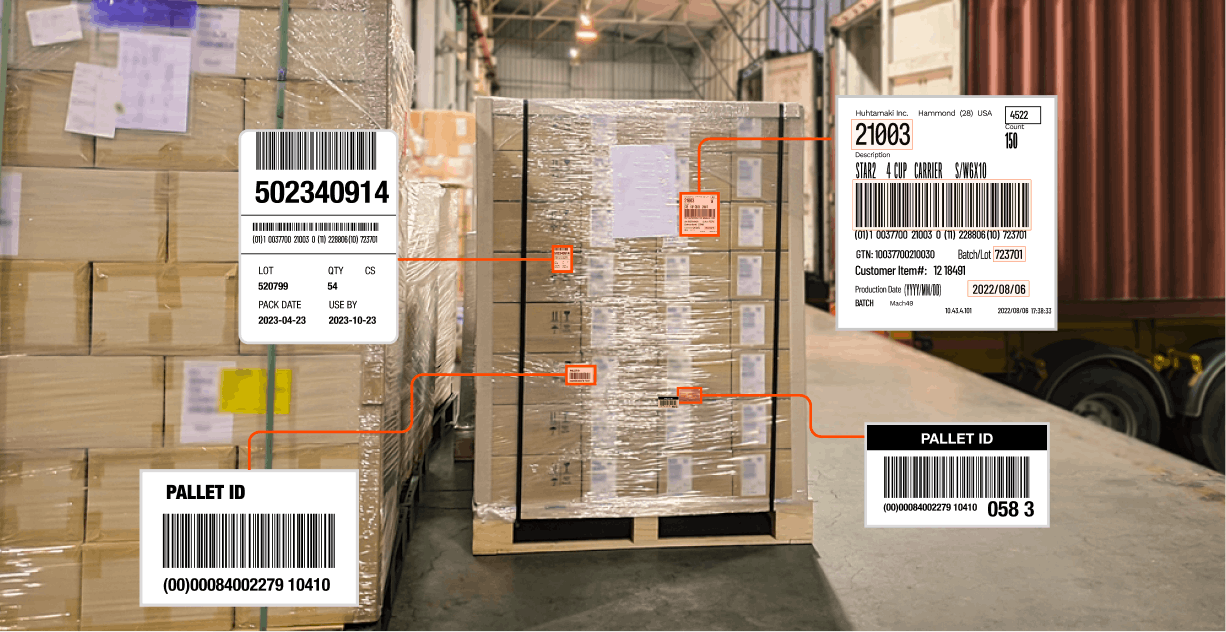

Dock door automation means using technology to scan and track every pallet that comes in or goes out—without stopping the flow of work. Instead of someone jumping off a forklift to scan barcodes or check a clipboard, smart scanners at the dock do the job automatically. These scanners can read labels, take pictures, and even spot damage. All the info goes straight into your warehouse system without delay. That means less human error and more time to focus on the real work.

The Real Cost of Manual Dock Operations vs. Automated Dock Systems

Doing things by hand slows everything down. Forklifts have to stop so someone can scan a pallet. Workers might miss a barcode or write down the wrong number. That leads to lost products, wrong shipments, and unhappy customers. It also costs you money—in overtime, in chargebacks, and in time spent fixing mistakes. Automated loading dock systems reduce these costs significantly by removing repetitive tasks and streamlining workflows.

How Dock Door Scanning Works (Step-by-Step Overview)

When a pallet rolls up to the dock, a scanner takes a photo and grabs the barcode. Some systems also read dimensions or catch signs of damage. All this happens while the forklift keeps moving. The data gets sent to your WMS, like Manhattan, Blue Yonder, or SAP, right away. No stopping, no waiting, and no clipboards.

Benefits of Loading Dock Automation for Warehouse Operations

The biggest win is speed. Pallets move in and out faster, and dock doors don’t get blocked. You also need fewer people to do the same work. Because every scan is automatic, you get fewer errors and more accurate data. Plus, your team can focus on bigger problems instead of chasing paperwork. With smart loading dock automation, some operations have seen up to 30% faster throughput and 80% fewer OS&D issues.

Where Automated Dock Systems Make the Biggest Impact

If you work in cold chain logistics, food and beverage, or high-volume distribution, dock door automation helps a ton. It’s especially useful when labels are hard to read, like when they’re under shrink wrap or in bad lighting. It also helps track lot codes and expiration dates for safety. In retail, it keeps you from sending the wrong thing to the wrong store. And for 3PLs, it gives clients the real-time data they expect from a modern warehouse dock automation platform.

Getting Started with Loading Dock Automation: Timeline and Requirements

First, pick a dock that causes the most issues. That’s where you should start. Look for an automated dock system that works with your current WMS, whether it’s Manhattan, Oracle, or NetSuite. The hardware should be easy to install, with minimal IT support. Kargo offers a fast-deploy trial that typically takes under 48 hours to install, letting you test real results quickly before scaling.

Manual vs. Automated Docks: What’s the Difference?

Manual docks rely on human input for scanning, data entry, and exception handling. This leads to delays, errors, and extra labor costs. Automated dock door scanning systems handle all of that in real time, with higher accuracy and lower labor demands. You don’t just save time—you avoid costly mistakes. Automation also gives you structured, actionable data from the moment freight hits the dock.

Common Concerns About Loading Dock Automation

Some teams worry automation will be too expensive or hard to install. In reality, many systems are modular and don’t require major infrastructure changes. Others worry about training, but modern dock door scanning systems are built to be user-friendly with minimal training required. The upfront investment often pays off in less than a year thanks to labor savings and reduced chargebacks.

Conclusion: Your Dock Door Is Your Data Source

The dock isn’t just where things move. It’s where data starts. When you automate scanning at the dock, you get better data, faster shipments, and happier teams. You also stay ahead in a world where speed and accuracy aren’t nice to have—they’re expected. Ready to try it? Let’s talk.

FAQs: Loading Dock Automation

What is automated dock door scanning? Dock door scanning uses computer vision or RFID to automatically capture barcode and pallet data as it moves through a dock door. It removes the need for manual barcode scanning.

How does dock door automation integrate with my WMS? Most smart loading dock systems integrate with popular WMS platforms like Manhattan, SAP, Blue Yonder, and NetSuite through API or middleware connectors.

What’s the ROI for warehouse dock automation? Customers typically see ROI in under 12 months through reduced labor, improved accuracy, and better dock throughput.

Is installation disruptive? Not at all. Most systems, including Kargo’s, install in under two days without requiring major changes to your dock setup.

What types of warehouses benefit most from loading dock automation? Cold chain, 3PLs, food & beverage, and high-velocity retail facilities benefit most—especially those with tight OTIF requirements or lots of receiving volume.

How does this compare to RFID? RFID is helpful but requires perfect tag placement and adds cost. Vision-based scanning captures more data with fewer limitations, especially in mixed-label environments.

Questions?

Connect With us

Ask us anything or drop your email to stay in touch