Kargo System

Warehouse AI Meets Automated Dock Doors—Introducing Kargo Intelligence

| Kargo | 5 min

Most operations leaders know the scramble that follows any data question on the dock: “Why was this shipment short?”, “Who caused that damage?”, or “How many pallets did we really move last night?” Emails fly, spreadsheets open, and hours vanish. OS&D (overages, shortages, damages) may be the most painful symptom, but it’s only one of many back‑office tasks that burn time—think ASN mismatches, billing disputes, labor‑productivity audits, and more.

Kargo Intelligence was built to take the load off every back‑office workflow. Powered by warehouse AI, smart dock doors, and end‑to‑end warehouse automation, it lets you ask plain‑English questions and get traceable, data‑backed answers in seconds—whether the topic is OS&D, inventory accuracy, carrier compliance, or labor planning.

What Exactly Is Warehouse AI?

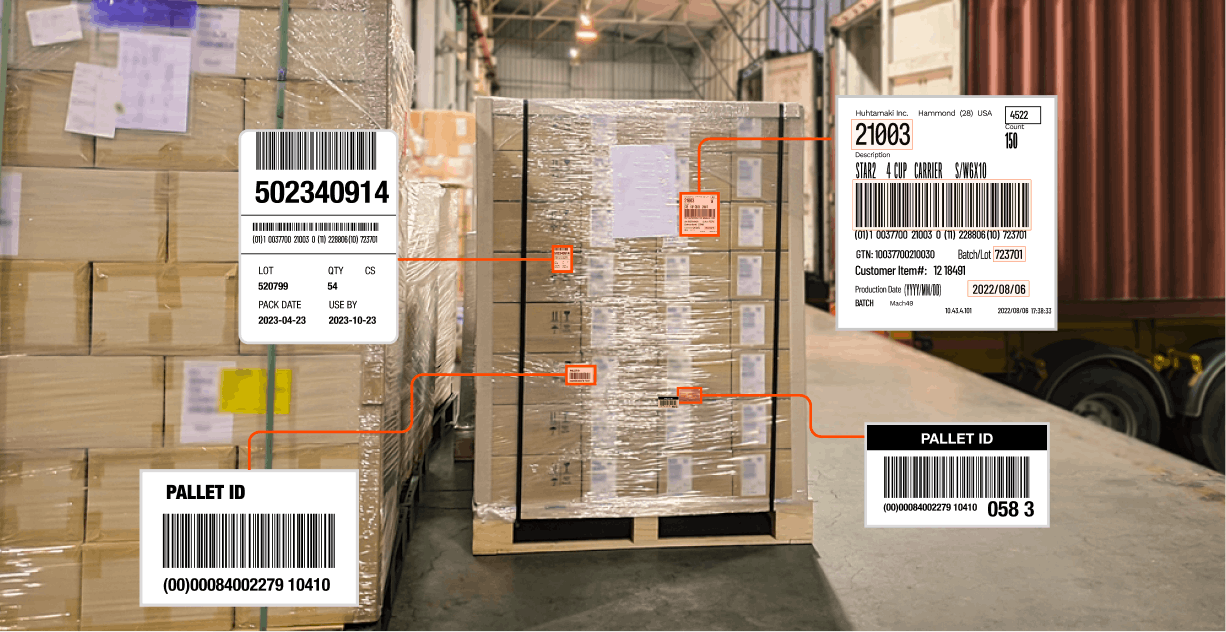

Warehouse AI blends computer vision, machine learning, and real‑time data fusion into a single, decision‑ready brain for your facility. Classic automation moves boxes faster; Warehouse AI adds the context that answers why, how, and what’s next. Perception – Cameras, RFID, and IoT sensors identify every pallet, SKU, forklift, and badge swipe. Reasoning – Algorithms connect those events to POs, shifts, carriers, and SLA targets. Action – Chatbots, alerts, and automated documents resolve issues before they cost money. Plug that loop into an automated dock door and you move from reaction to proactivity—across all back‑office processes.

Why OS&D (and Its Cousins) Still Bleed Money

80 % of U.S. warehouses still rely on clipboards and disconnected scanners¹. Labor consumes 50–70 % of operating budget². Manual data entry errors hover at 4 %³. Charge‑backs for OS&D, ASN failures, and late shipments siphon 1–3 % of annual revenue⁴ ⁵. Traditional dashboards are backward‑looking; they show you what happened after the checks cleared. Kargo Intelligence brings Warehouse AI right to the dock door so you can prevent, not just report.

AI and Dock‑Door Automation: Kargo Intelligence

A sensor‑only dock sees pallets; a smart dock door understands them. Kargo Intelligence overlays vision, WMS/TMS feeds, and IoT events with a language interface. Ask: “Which vendors caused the most OS&D exceptions this quarter?” “What shift has the highest labor cost per pallet?” “Flag any ASN that missed today’s 08:00 cut‑off.” You get narrative answers, charts, and—when needed—annotated video clips. Because the system already knows the PO, pallet ID, and time‑stamp, there’s zero swivel‑chair work.

Automated Dock‑Door Workflows for the Modern Back Offices

Inbound OS&D — Claim Filed Before the Trailer Pulls Away

- Auto‑captured context – Date, time, dock, PO, vendor, carrier, pallet barcode auto‑fill.

- AI‑suggested reason code – Vision classifies damage (puncture, crush) and proposes the OS&D code.

- Curated visual evidence – The clearest frames attach automatically; operators tick to confirm.

- Dynamic routing – Vendor and SKU drive the correct email group; CCs or escalations in one click.

- One‑tap submission – A PDF with video proof and JSON payload ships instantly; everything is hash‑logged for audit.

Impact: Real‑time vendor scorecards replace month‑end guesswork. Suppliers are fined for the damage they cause, not you.

Outbound Accountability — No More He‑Said‑She‑Said at the Gate

- Real‑time damage detection – Vision flags crushed wrap or leaning stacks as the pallet exits.

- Pre‑filled claim – Order, shift, carrier, destination, temp‑zone, forklift ID auto‑populate.

- Root‑cause tagging – Operator confirms “forklift handling” vs. “dock collision”; data feeds safety heat‑maps.

- Chain‑of‑custody video – Ten‑second loop ties incident to operator badge.

- Live KPI push – Customer service, finance, and transport dashboards refresh immediately.

Inventory & ASN Reconciliation — From Days to Seconds

- Product‑cut workflow – Auto‑fills PO, expected vs. actual count, suggests reason, embeds photos.

- ASN integrity check – Compares supplier data to camera counts; flags mismatches instantly.

- Multi‑incident correlation – Query: “Suppliers with repeat ASN failures and cost YTD.”

- Predictive alerts – AI warns when ASN accuracy trends downward, projecting potential charge‑backs.

Labor & Compliance Dashboards — One System, All Metrics

- Shift productivity – Pallets per labor‑hour, by dock door and role.

- Carrier compliance – On‑time arrivals, dwell time, damage incidence.

- Safety audits – Forklift speed, proximity alerts, PPE detection (coming soon).

Because these outputs share a single warehouse AI spine, leadership toggles from a 30‑day KPI to frame‑level evidence in seconds.

FAQ — Beyond OS&D: Every Back‑Office Question, One Chat Away

Does Kargo Intelligence only handle OS&D?

No. OS&D is a high‑ROI entry point, but the chatbot also tackles ASN mismatches, inventory audits, labor analysis, and carrier compliance—anything captured by our vision and data integrations.

Can I upload facility‑specific codes or workflows?

Yes. Add local reason codes, cost centers, or approval steps. The system retrains weekly without disrupting live ops.

What about sites without Kargo cameras?

You’ll still get cross‑system analytics via WMS/TMS, but adding vision unlocks image proof, worker attribution, and zero‑click claims.

How do I prove ROI?

Every answer tags avoided claims, hours saved, and SLA gains. Most sites see payback in under 90 days.

Is it audit‑ready?

All queries and evidence are hashed and stored immutably. Export ISO/FDA audit trails with one click.

Will my data be shared?

All Kargo customer data is siloed and customers will only be able to interact with their data through Kargo intelligence.

From Reaction to Proactivity with AI in the Warehouse

If surprises—from OS&D to late ASNs—still ambush your P&L, your warehouse automation stack isn’t intelligent enough. Kargo Intelligence merges warehouse AI with smart dock‑door automation, surfacing answers the moment freight crosses your automated threshold—and presenting them in plain English.

Ready for a live look? Book a five‑minute walkthrough and watch your entire back‑office workflow light up.

Sources

- NAIOP, The Future of the Warehouse: Automated Smart Buildings, Spring 2024.

- Canon Business Process Services, Three Key Cost‑Saving Strategies for Warehouse Operations, 2025.

- ConnectPointz, How Manual Data Entry and Human Error Are Costing You Money, 2025.

- eFulfillment Service, The Meaning of OS&D: Impact & Insights, Dec 2023.

- Kargo & FreightWaves, 3 Ways to Control Spending on OS&D, Jan 2024.

Questions?

Connect With us

Ask us anything or drop your email to stay in touch